The Process

Step 1: Artwork

I create bronze sculptures using clay, foam or wax.

After I create a small piece, it goes directly to mold making. For monumental sculptures, the next step is “pointing up” which is a process that takes the small sculpture (the maquette) and enlarges it to any size.

Step 2: Molds

My staff artisans and I will study the sculpture and make a determination on how the sculpture will be sectioned or “laid up” for mold making. Complex molds will require the original artwork to be cut into smaller manageable pieces. This is, by far, the most critical step of the procedure. The details of the original must be captured and transferred in the mold. If not, they will be difficult to replace in any other step.

The sculpture is first sealed and then a release agent is applied to allow for easy removal of the rubber mold. Depending on the requirements of the piece we will create a silicone, latex, or polyurethane mold. After the original sculpture has been prepared, the master mold maker will apply the first coat of rubber. Once the rubber has set, additional coats must be applied and “keys” will be placed in the rubber to ensure proper positioning of the mold. When the rubber is thoroughly set, a back-up shell or “Mother Mold” is applied to support the rubber for the wax pouring process. Previously, plaster was used for this process. Today, the most widely used material is fiberglass due to its strength, durability and, it weighs much less than plaster. A release agent is applied on one half of the rubber mold, then the fiberglass is laid down on the rubber, followed by the resin and it is allowed to dry. Depending on the size of the mold and the strength needed, several coats may need to be applied. Then the mold and mother mold are flipped over and the process is repeated on the other half. The back-up shell is removed and the rubber gently pulled back so the original sculpture can be removed. The rubber is then cleaned of any remaining particles from the original. It is now ready to receive the wax.

Step 3: Wax Casting

The completed mold, having already been prepped, is now ready for the wax. The mold is separated and the first coat of wax is painted into the mold to capture all the fine details of the artist’s masterwork. The mold is put together and more wax is poured in. It is then rotated until an even, thin coating is achieved. Once it has cooled, a second coat is applied and rotated to achieve a thickness of 3/16 to 1/4 of an inch. The excess wax is poured out. After the wax has completely cooled, the “mother mold” followed by the rubber mold is removed. Now the wax casting is revealed.

Step 4: Wax Chasing (a technique used to define or refine the forms of a surface design)

Seam lines are removed and the wax pieces are fitted for alignment. Then the register marks are put in, followed by the final wax inspection.

Step 5: Spruing & Gating

Wax rods are attached to the sculpture. These rods are called sprus or gates. A large cup is attached at one end, this cup will receive the molten bronze when poured. The placement of the gate system allows molten bronze to flow through these areas allowing gases to escape through smaller bars called vents.

Step 6: Ceramic Shell

We now make a secondary mold. Though the materials are much more modern, this serves the same function as mud did 5,000 years ago. We now dip the wax in a liquid binder solution. This material is called “slurry” and a very fine silica sand is applied. Each coating is completely dried prior to the next. The number of coats applied to a piece is determined by the size and weight of the piece. The heavier the piece the thicker the shell must be to support the metal. The slurry coats the inside and outside of the wax allowing the sculpture to be hollow. The chemical make-up of the slurry is monitored constantly to ensure it’s strength. The humidity and temperature of the slurry room is controlled to allow for optimum dryness and hardness of the shells.

Step 7: Metal Casting

The ceramic shell is placed in an autoclave (or a burn-out oven) cup side down. A burn-out oven is simply a large flame-heated oven, an autoclave is a large machine that heats up under steam pressure. Either method will allow the shells to de-wax. Once the shells are de-waxed, they are cooled and inspected for cracking. Once again they are heated up to 1400 degrees and placed in the pouring pit. Bronze ingots are heated from 1900 to 2100 degrees. The temperature that bronze is poured is determined by each individual casting. The molten bronze is then poured into the hollow shells and allowed to cool and solidify.

Step 8: Devesting

The shell material is now removed inside and out, and the unfinished bronze casting is revealed. It is then glass beaded, water or sand blasted to remove any remaining shell material from the intricate details of the casting.

Step 9: Welding

If the original sculpture was sectioned into multiple pieces, it would now be carefully fitted and reassembled. A visual inspection is done to check for any casting inclusions. If there are any surface defects, these would also be repaired at this time. All sections of the casting are welded together with great care and attention to alignment.

Step 10: Metal Chasing

The sculpture is chased to remove any sign of welding or casting defect and to prepare the bronze for the patina (coloring process).

Step 11: Glass Beading

We use a wide variety of polishing and detail tools without disturbing the original texture of the sculpture. A final metal inspection is performed at this stage of the process.

Step 12: Patination

The patina is the finished color. I use a variety of different chemicals which react to the metal to achieve the exact look that I desire.. After the patina is applied, I work with dyes and coloured waxes, to achieve the exact unique look that I desire. Depending on whether the artwork will be inside or outside, the sculpture is then sealed with a wax coat and/or lacquer to protect the finish.

Step 13: Crating & Shipping

The sculpture is carefully and securely packaged (in a wooden crate for heavier pieces) for safe shipping.

Step 14: Delivery

Safe delivery of the final product completes the process.

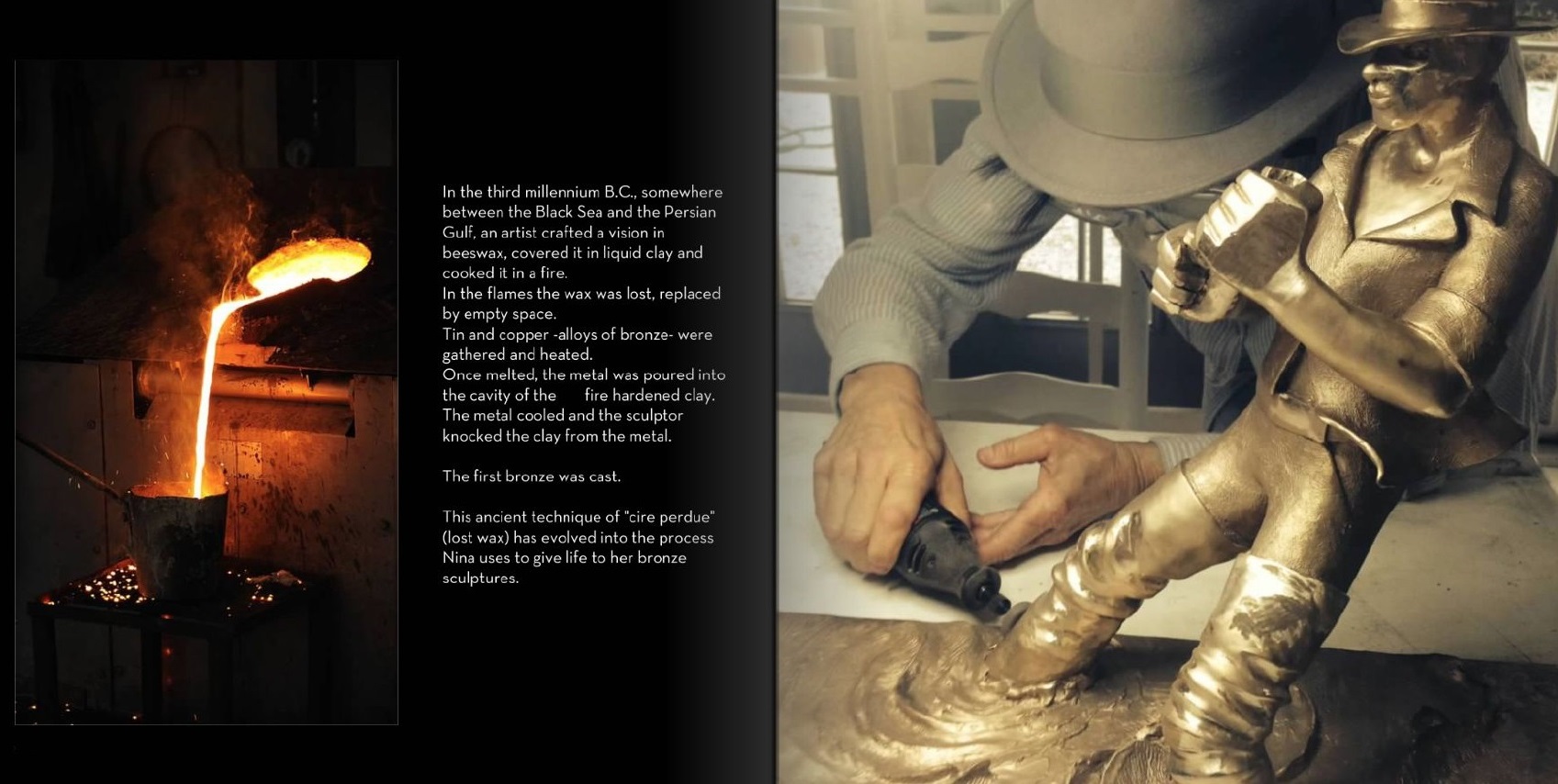

History of Bronze

Bronze was significant to any culture that encountered it. It was one of the most innovative alloys of mankind. Tools, weapons, armor, and various building materials like decorative tiles made of bronze were harder and more durable than their stone and copper predecessors. Initially bronze was made out of copper and arsenic to form arsenic bronze. It was only later that tin was used, becoming the sole type of bronze in the late 3rd millennium BC. Tin bronze was superior over arsenic bronze in that the alloying process itself could more easily be controlled (as tin was available as a metal) and the alloy was stronger and easier to cast. Also, unlike arsenic, tin is not toxic.

The earliest tin-alloy bronzes date to the late 4th millennium BC in Susa and some ancient sites in Luristan and Mesopotamia.

Copper and tin ores are rarely found together (exceptions include one ancient site in Thailand and one in Iran, so serious bronze work has always involved trade. In Europe, the major source for tin was Great Britain’s deposits of ore in Cornwall. Phoenician traders visited Great Britain to trade goods from the Mediterranean for tin.

Bronze is widely used for casting bronze sculptures. Many common bronze alloys have the unusual and very desirable property of expanding slightly just before they set, thus filling in the finest details of a mould. Bronze parts are tough and typically used for bearings, clips, electrical connectors and springs.

Bronze also has very little metal-on-metal friction, which made it invaluable for the building of cannon where iron cannonballs would otherwise stick in the barrel. It is still widely used today for springs, bearings, bushings, automobile transmission pilot bearings, and similar fittings, and is particularly common in the bearings of small electric motors. Phosphor bronze is particularly suited to precision-grade bearings and springs. It is also used in guitar and piano strings.

Bronze is typically 88% copper and 12% tin.

Commercial bronze (otherwise known as brass) is 90% copper and 10% zinc, and contains no tin. It is stronger than copper and it has equivalent ductility. It is used for screws and wires.

Unlike steel, bronze struck against a hard surface will not generate sparks, so it (along with beryllium copper) is used to make hammers, mallets, wrenches and other durable tools to be used in explosive atmospheres or in the presence of flammable vapors.

Indian Hindu artisans from the period of the Chola empire in Tamil Nadu, used bronze to create intricate statutes via the lost wax method with ornate detailing depicting the Gods of Hinduism mostly, but also the lifestyle of the period. The art form survives to this day, with many silpis, craftsmen, working in the areas of Swamimalai and Chennai.

In antiquity other cultures also produced works of high art using bronze. For example: in Africa the bronze heads of the Kingdom of Benin, in Europe; Grecian bronzes typically of figures from Greek mythology, in east Asia; Chinese bronzes of the Shang and Zhou dynasty – more often ceremonial vessels but including some figurine examples.

Bronze continues into modern times as one of the materials of select choice for monumental statuary.